Our current project answers the need for a versatile pc based programmable Functional Test System with interchangeable fixture cartridges, with data logging capability, housed within a sturdy cabinet with space for instrumentation and other controls. This project actually included a dual application set of systems: One for the CEM manufacturing floor to test their pneumatic controls, and another at the OEM for the finished control box testing before installation.

When meeting a Functional Test Challenge, IQ intuitively designs and develops systems that can grow with the future needs of the company. Those characteristics are:

Customizable – Versatile – Innovative

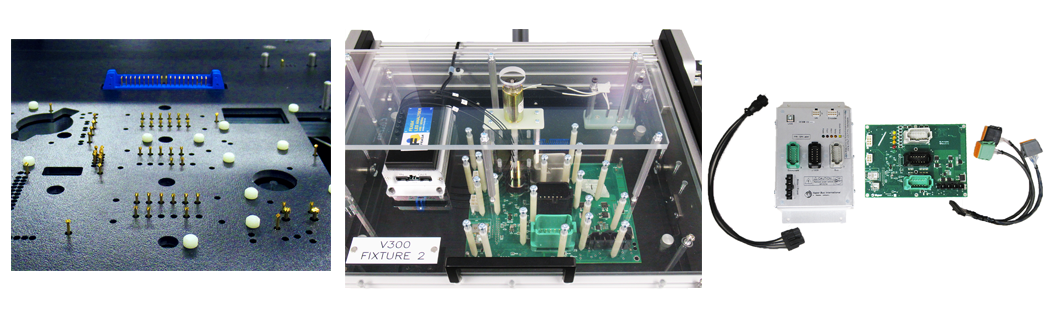

Customizable: Readily Inter-Changeable Fixtures to transform to your changing needs.

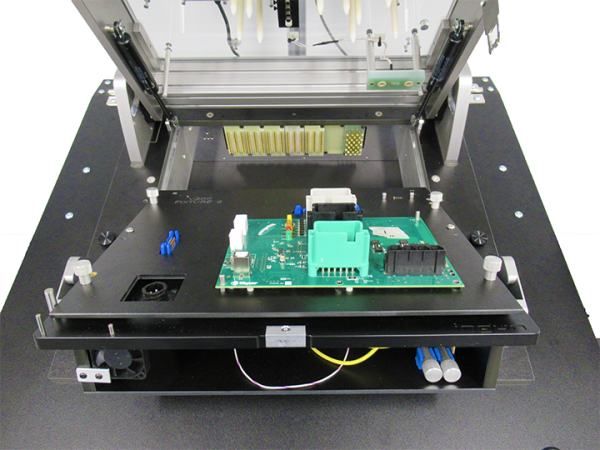

Versatility – The IQ Framework Cabinet: Our IQ testers are built on a sturdy wheeled cart for easy transport to various manufacturing floor locations. The Framework cabinet has 2 drawers with front or rear sliders for computers, power conditioners, pneumatic controls, or other instrumentation through four locking access door panels. If you require new boards, devices or firmware, this addition is easily accomplished, as your manufacturing floor adapts to your future requirements.

Innovative: Fixture Drawer Shield – exclusive interior dust cover to protect fixture wiring from dust and falling objects.

IQ’s Functional Test Fixtures:

Hardware:

- USB Instrumentation

- XJTAG boundary scan

- Data Acquisition

- PC Workstations

- Test Fixtures

Applications:

- Circuit Boards

- Assemblies

- Cabinet Harnesses

Software:

- LabVIEW

- LabWindows/CVI

- Visual Basic

- .Net

Services:

- Testability assessment (DFT)

- TRD/Test plan development

- Flash, FPGA, CPLD programming

Posted by Admin

Posted by Admin