Over the years I have seen hundreds of different custom circuit board testers. Here at IQ alone we have completed over 2500 projects. But I am also constantly checking out my competitor’s work. I have seen really nice systems where the builders knew what they were doing and accomplished their goals well. Some of these almost rise to the level of commercial ATE.

But I have also seen some real dogs. I can even think of a few projects where we missed the boat and shipped something less than elegant. I have been able to identify three things that enable the successful build of a test system. “Successful” as measured by its ability to satisfy the needs of the user, and be built on time and on budget.

1. The skill set of the building organization.

2. A realistic budget.

3. An appropriate identification of the major requirements.

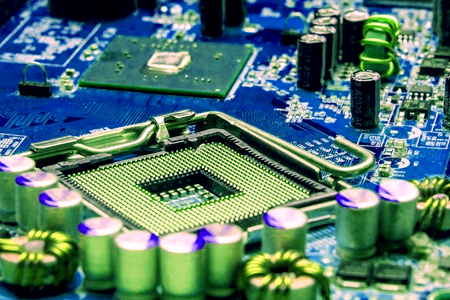

1. The first one is surprisingly overlooked. To be successful designing and building a test system requires a knowledge of designing and building test systems. Designing printed circuit boards doesn’t educate an engineer on how to design a tester. Today’s testers require knowledge and experience in a diverse set of disciplines.

Many of the dog testers I have seen were hastily thrown together by product designers who had no idea of test system state of the art or the requirements for use on a factory floor. Others were built by techs or even interns on their first project. No surprise when the tester is deficient.

When we hire a fresh-out we look for top notch graduates. Then we assume (correctly) they have no idea what we are doing. We figure it takes over a year and several projects with close guidance before a young engineer begins to understand.

2. Of course a realist budget is necessary. When an unrealistic budget is ordained prematurely, it is a set up for a failure that can be several times more costly than a properly budgeted tester. Poorly built testers on a shoestring budget will underperform. Production goals will be stymied. Engineering resources will be poured into attempting to resolve a mess. Often the end result is a walk away with a half-solved problem. It is amazing how many test systems are running poorly and robbing their owners of potential profits.

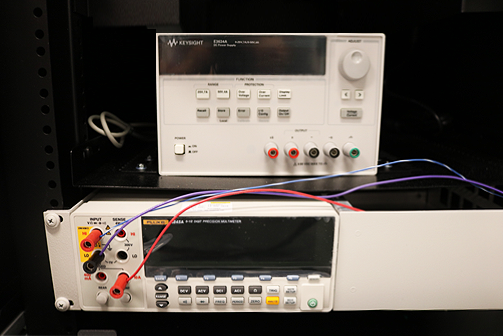

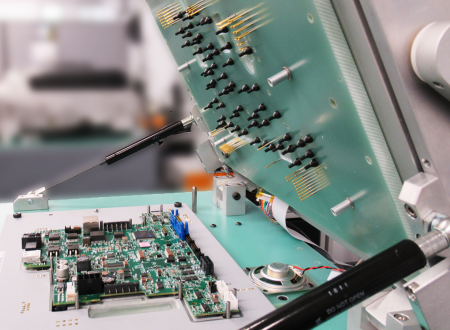

3. But the intent of this note is to shine a light on the third enabling requirement. Test requirements are usually mentioned for sure, but often without adequate emphasis. People often assume that a tester is a known entity. “Just test it and tell me if its good or bad.” Unfortunately, there is so much more. Getting the necessary tech data is sometimes hard, but most folks recognize the need for data. The CAD data, BOM and drawings are usually available. But it is rare that the tech data includes test requirements. The test system designers need to know what are the characteristics and properties of the device that you would require be tested. The designers will need to know levels and accuracies so they can select and quote appropriate instrumentation.

A good design will have an awareness of the intended use. Is this going to be used for a single product? Or are there several similar products that might use the same basic design? What is the production volume? The design of a tester for 100 boards a month will be significantly different from a design for 10,000 boards a month.

Good test system designers know what is available on the market. Not only for standard measurement instrumentation but also for unusual test requirements. Measuring LED intensity and color, actuating switches automatically, communicating with NFC devices or loading flash firmware are examples of tester features that might be overlooked. There are dozens more that a competent test engineer might recommend.

Too often I have seen requirements written for the operator to read and verify some aspect of product performance. Generally this is asking for trouble. Operators will miss or misinterpret errors. Faults will get passed. The cost of single passed fault can easily exceed the cost of good test automation.

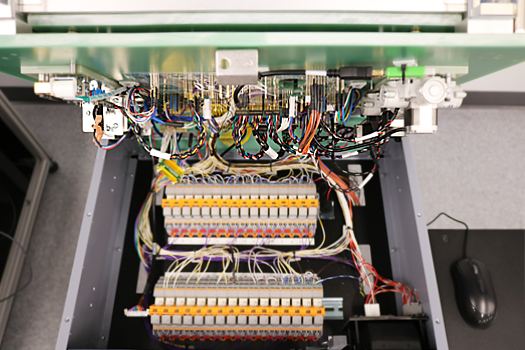

There are so many aspects like handling, safety, locking the fixture closed, data collection. So many others that could easily be overlooked and yet could be a big contributor to success or failure. The test requirements far exceed just a detailed description of the product. To determine the test system design requires a thorough understanding of the product, the use of the test system and how test systems are built with today’s technology to meet the needs of both the owners of the product and also the performers of the test.

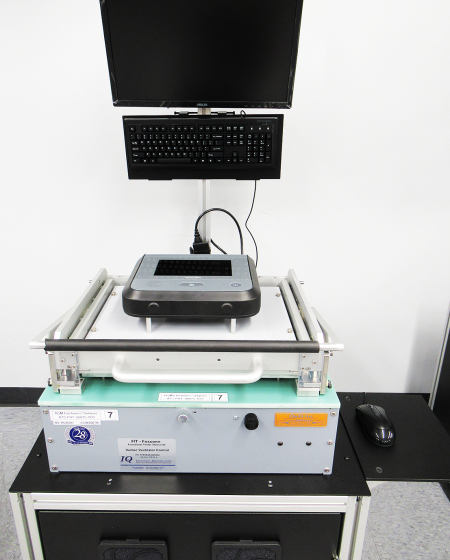

Intrinsic Quality, LLC has over 35 years of experience in engineering and developing Automated Test Systems. We are experts in electronics manufacturing and test engineering. IQ is dedicated to the development of superior engineering and comprehensive ATE solutions for the electronics manufacturing, automotive, aerospace, military and medical industries.

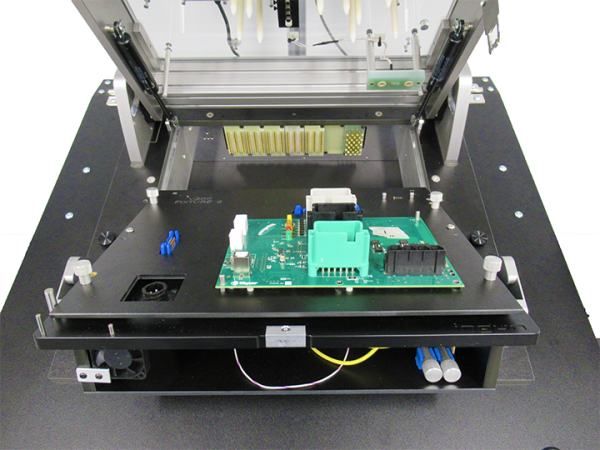

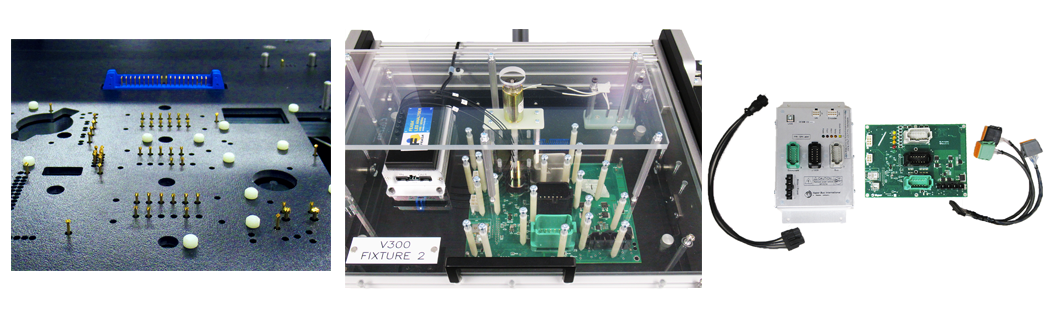

Our solutions include Functional and ICT Test Systems and Fixture development as well as Microcontroller Flash Fixture Programming.

For additional information, please Contact Intrinsic Quality or call IQ at 847-258-5598.

Posted by Admin

Posted by Admin