Many manufacturers who specialize in high volume continuous production choose to use a dedicated Flash programming station to meet their needs. This can make a lot of sense whether it is implemented as an automated in-line system or as a manually handled station. Often the extra time at ICT or EOL FCT is too costly, so a separate station works well.

But for the CEM who deals with a high mix of relatively low volume production, it would seem that a separate station makes no sense at all. But in reality, the “high-mix” feature can have significant impact.

For most of the controls being produced, flashing as part of the production process is a requirement. Often, the flashing solution is provided by the customer. It may be a spin-off of the unit used in software development. It is likely relatively unique and typically requires rather cumbersome operations.

When the CEM is “blessed” with several different versions of these solutions, they can become a drag on productivity. Set up and take down is time consuming or keeping the station installed uses valuable shop space. Since each setup has a unique operation, either skilled operators or ongoing training are required. Then because the station was not likely designed to be production line robust, maintenance can be a serious problem.

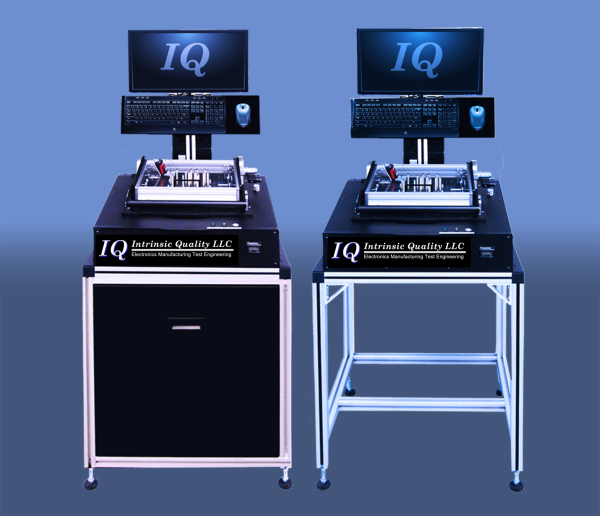

It should be no surprise that the high-mix CEM is faced with these problems. They are part of what he is paid to solve. But there is an alternative that is not terribly expensive and solves these problems. It is a programming station designed for the High Mix environment. Intrinsic Quality LLC in Elk Grove Village, IL manufactures just such a machine.

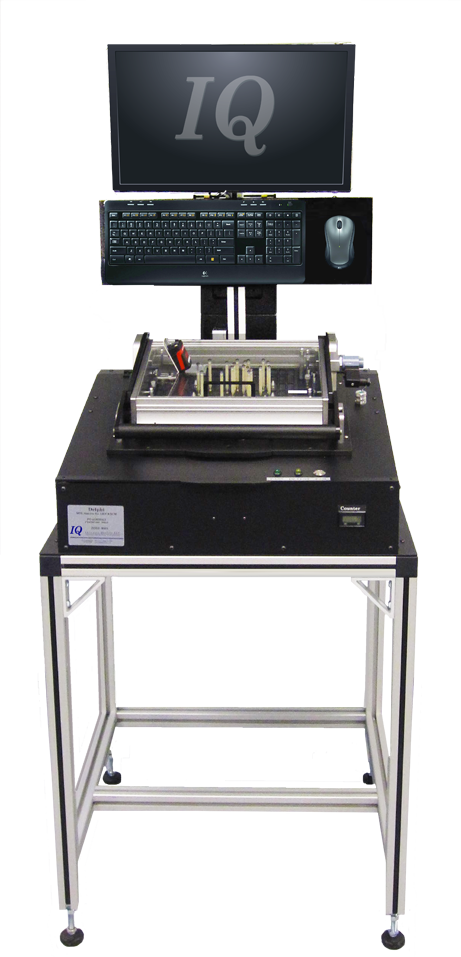

The IQ Programming Station is based on the SMH Technologies FlashRunner. Like the FlashRunner programmers, the stations are highly configurable. First, they have the capability of programming any microcontroller or memory device. Next the production setup for any particular control is quick and easy. It could be as easy as selecting the product name from a list and using the designated cable harness. Or if volumes justify or board design requires, a change of the bed of nails fixture can easily be made. The system guides the operator throughout the process and records all transactions. If serializing is needed, a printer can be easily attached to print labels.

Even if the customer provides the flash programming setup, converting this to use the IQ Programming Station is straightforward and worthwhile.

Yes, there is the question of capital cost. But this can easily be recovered by the reduction in operational costs.

Our solutions include Functional and ICT Test Systems and Fixture development as well as Microcontroller Flash Fixture Programming.

For additional information, please Contact Intrinsic Quality or call IQ at 847-258-5598.

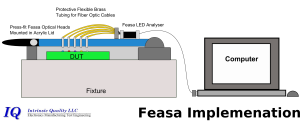

There’s still time to join SMH Technologies and IQ for an informative seminar on Universal In-System Programming on April 5, 2024 in Novi, MI. We’re featuring a morning and afternoon in-depth presentation by Mr. Ivan Rinaldi and Mr. Moreno Ortolan of SMH. Learn more about programming Flash Devices, Ingun Bed of Nails Fixtures and Feasa LED analytics. RSVP: larry.raymond@intrinsicquality.com

Posted by Admin

Posted by Admin

Please join Intrinsic Quality at the Automotive Testing Expo in Novi, Michigan on October 22 through 24, 2019. IQ will be showcasing our Flash Device Production Programming Station and the new line of SMH FlashRunner Products at Booth #15038. IQ’s Programming Stations are designed to provide a comprehensive solution for loading firmware for powertrain and ADAS applications.

Please join Intrinsic Quality at the Automotive Testing Expo in Novi, Michigan on October 22 through 24, 2019. IQ will be showcasing our Flash Device Production Programming Station and the new line of SMH FlashRunner Products at Booth #15038. IQ’s Programming Stations are designed to provide a comprehensive solution for loading firmware for powertrain and ADAS applications.

Our Prodigy 1011 is a stand-alone microcontroller based programmer (no well) that is set up for an external harness or fixture. The 1011 is our response to the need for an affordable production ready, high speed, entry level programming station. Based on the SMH FlashRunner FR01ENG, Prodigy 1011 is the perfect answer to low volume high mix manufacturers who previously could not justify a commercial programming station. The Prodigy 1011 is remarkably capabable of adapting to multiple devices, protocols and various vendors for long-term functionality. Adaptability: Auto selection of part number is based on a 5 bit ID provided by the fixture or ATE OR for higher volume applications, the 1011 connects readily to simple interchangeable bed of nail fixtures. In ATE applications, Prodigy easily connects to the ATE fixture with auto detect remote operation. Prodigy 1011’s throughput is impressive, as production can move rapidly with minimized operator error and lightning fast programming times. View all of IQ’s Prodigy 1011 features

Our Prodigy 1011 is a stand-alone microcontroller based programmer (no well) that is set up for an external harness or fixture. The 1011 is our response to the need for an affordable production ready, high speed, entry level programming station. Based on the SMH FlashRunner FR01ENG, Prodigy 1011 is the perfect answer to low volume high mix manufacturers who previously could not justify a commercial programming station. The Prodigy 1011 is remarkably capabable of adapting to multiple devices, protocols and various vendors for long-term functionality. Adaptability: Auto selection of part number is based on a 5 bit ID provided by the fixture or ATE OR for higher volume applications, the 1011 connects readily to simple interchangeable bed of nail fixtures. In ATE applications, Prodigy easily connects to the ATE fixture with auto detect remote operation. Prodigy 1011’s throughput is impressive, as production can move rapidly with minimized operator error and lightning fast programming times. View all of IQ’s Prodigy 1011 features  IQ‘s Prodigy 2000 single or dual well programmer stations are desogmed fpr easo;u interchangeable fixtures and include Intrinsic Quality‘s expert device programming services. All programming parameters are included as firmware revision, power, and signal levels are automatically verified and set up. The Prodigy 2111 and further models are available in an amazing variety of configurations that include single or dual well and multiple channel capabilities. For more information, visit our

IQ‘s Prodigy 2000 single or dual well programmer stations are desogmed fpr easo;u interchangeable fixtures and include Intrinsic Quality‘s expert device programming services. All programming parameters are included as firmware revision, power, and signal levels are automatically verified and set up. The Prodigy 2111 and further models are available in an amazing variety of configurations that include single or dual well and multiple channel capabilities. For more information, visit our

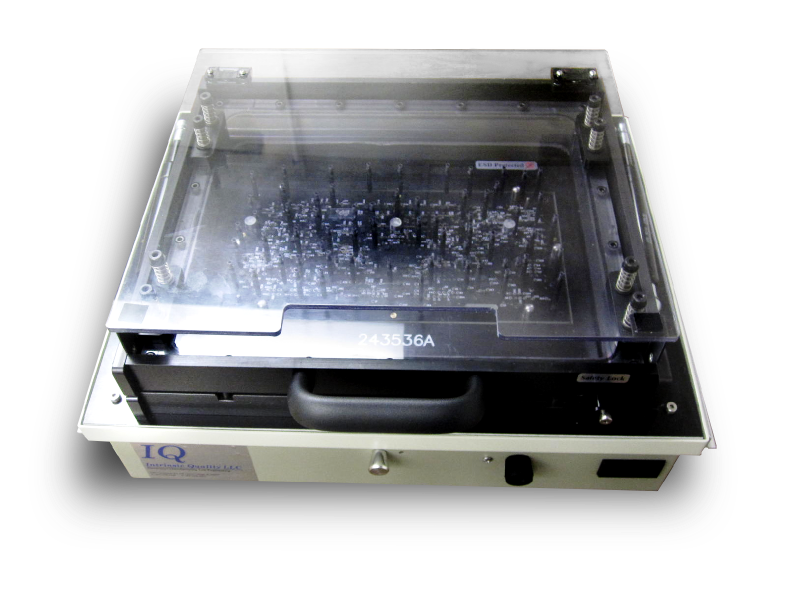

Custom FlashRunner Fixture

Custom FlashRunner Fixture